To bring the best organic dried mango to the European market, our Purchasing Manager, Emilie recently embarked on a journey to Burkina Faso and Ivory Coast. Her mission: to visit and qualify top organic dried mango producers, ensuring they meet our rigorous standards. Here’s an in-depth look at her findings and the unique qualities of these two West African countries.

Burkina Faso: Tradition Meets Quality

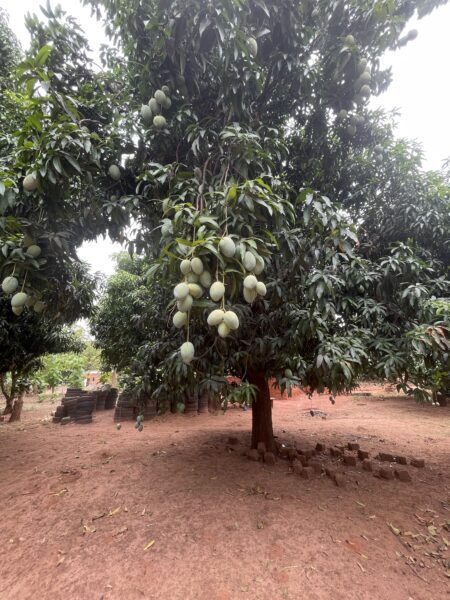

Burkina Faso has a tropical climate with distinct wet and dry seasons, creating perfect conditions for mango trees to thrive. While wild mangos grow abundantly, they are too fibrous for drying purposes. Instead, the focus is on cultivated varieties, where the wild mango is crossed with specific types in a controlled environment.

Mango Varieties

Burkina Faso grows various types of mango – the Brooks variety stands out and is sought after by our clients due to its sweet and tangy flavour profile especially good for drying. Other well known varieties are Amelie, which is quite tart and tangy and then Lippens and Kent – both sweet and used mainly for fresh export.

Historical Expertise in Dried Mango

Burkina Faso holds a significant place in the dried mango industry. In the 1990s, a Swiss NGO initiated a program that laid the foundation and provided the first drying machines for organic mango production in the region. Despite some countries using more advanced technology, they have the original technologies and years of know-how, trial and error and today dried mango production employs thousands of women in Burkina. Some producers we met, still use the first ovens (although upgraded) developed in the original program as the heating principle is still the same to this day.

Production Process in Burkina Faso

Harvesting and Sorting

The mango season spans from April to June. During this period, mangos are harvested daily. Each variety has different ripening and maturity stages within that 3 month period; Amelie is the first one in April and then Lippens and Kent, and towards the end of the season in June, Brooks is ready for harvesting. So from the beginning of the first harvesting of Amelie to the final harvesting of Brooks, the procedures will get mangos every day.

Every day the first step is to sort through the batch of several tons of fresh mango and sort out the ones with dents, cuts, and are too ripe etc. Then they will sort by ripeness – the ripe ones will be cut the same day. Those that are not ripe enough are stored in clay baskets to accelerate ripening through generated heat.

Cleaning and Peeling

The ready mangos are then cleaned and rinsed and then transferred by the moving team to the peeling team consisting of women where they are meticulously hand peeled.

Cutting and Drying

Peeled mangos are then transferred to the cutting team who cut them into strips or cheeks. Next, the moving team will transfer the mango to the drying team who place the strips onto the drying trays and enter into the oven. The drying process is done in gas-heated ovens, where the temperature is kept between 60-65 degrees Celsius. Traditional ovens require manual rotation of trays to ensure even drying, while modern tunnel ovens provide a more uniform drying process.

Quality Control

After drying for approximately 18 hours, the mangos are checked for moisture content, color consistency and cleanliness before packaged in 1kg and 2kg bags and then loaded onto pallets.

Sourcing Criteria: Quality and Compliance

Hygienic Standards

Ensuring that producers adhere and comply with EU regulations is paramount. High hygienic standards must be maintained throughout the production process to guarantee a safe and high-quality product for our customers.

Moisture Content and Texture

The ideal dried mango should have a moisture content of around 12-18%, providing a chewy yet firm texture. Too much moisture makes the mango too soft, while too little makes it tough and hard to chew.

Colour and Consistency

A bright, consistent orange colour indicates a well-dried mango. Mango that is too dark in color is separated during the quality control step.

Ivory Coast: Innovation and Emerging Expertise

The Ivory Coast, located just south of Burkina Faso, enjoys a more tropical climate. The country is economically more developed, with modern infrastructure and advanced technology, which is evident in its mango drying industry.

Ivory Coast producers are leveraging advanced machinery to streamline the drying process. However, they are still in the phase of refining their techniques to achieve the same level of efficiency and quality that Burkina Faso has mastered over the years.

Social and Economic Impact

Supporting Local Economies

By sourcing from Burkina Faso and Ivory Coast, we support local economies, providing employment opportunities, especially for women. These partnerships promote sustainable practices and improve the livelihoods of local communities.

Ethical and Sustainable Practices

We prioritise working with producers who uphold ethical standards, including fair wages and good working conditions. Our focus on organic and fair-trade certifications ensures that our sourcing practices are both environmentally and socially responsible.

By sourcing organic dried mango from these regions, we ensure that our European market receives the best-tasting, highest-quality product while supporting ethical practices and local economies.

Embrace the delightful flavours of West Africa’s dried mango and join us in making a positive impact through mindful sourcing. Contact us today for more information on pricing, volume and delivery!

© Copyright Abbott Blackstone International GMBH