In July, we travelled to China to meet with our pea and rice protein powder producers. Our goal was clear: to ensure that every step in the production process upholds the high-quality standards we promise to our customers. What we encountered was impressive on every level, showcasing a dedication to innovation, scale, and purity.

Unveiling the Pea Protein Powerhouse

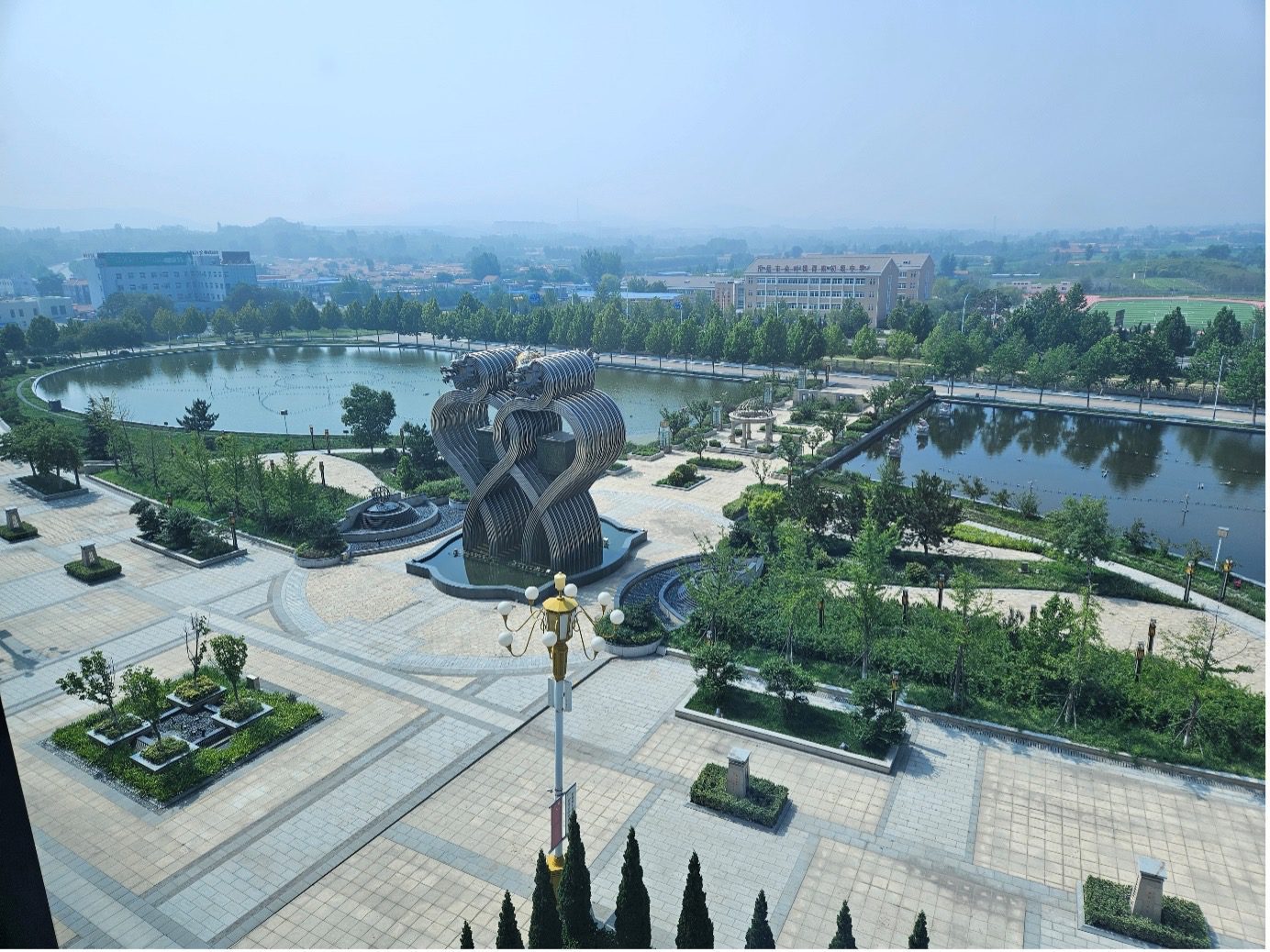

Our first stop was the pea protein facility. Calling it a facility hardly does it justice—it’s more like a self-contained city dedicated to producing pea protein at a large scale. Imagine pouring in half a million tons of peas at the start, and watching as this fully automated, high-tech, state-of-the-art system turns out separated starch and protein in high volume. It was unlike anything we’ve seen; a testament to both modern technology and an impressive commitment of our Chinese producer.

The structure of the facility is a feat of engineering. Spanning an area comparable to a small village, it even has its own dedicated power plant to meet the energy demands of such an extensive operation. This autonomy not only ensures efficiency but also contributes to a highly controlled environment so that purity and fineness of the powder can be 100% controlled and ensured batch after batch. The farming is done on their own large-scale organic pea plantations managed by their own subsidiary farming company.

Interesting trivia: originally their main product was the pure pea starch which was used to produce glass noodles “vermicelli“ and the pea protein was a by-product they achieved by sun drying. The glass noodles are still sold today domestically.

Today this global one-of-a-kind fully automated facility produces 50.000mt of pea protein per year – a truly global market player!

Making the Pea Protein

To make pea protein, dried yellow peas are cleaned and soaked and sieved. In a simple primary production step natural enzymes are added to the pea mash. These enzymes attack the starch (not the proteins) of the peas and break it down into smaller particles. This is the more natural approach leaving the protein molecules untouched and intact, resulting in great consistency with a very light colour and a very neutral taste. Other procedures like hydrolysis have a different approach: various enzymes attack and break down the protein (not the starch). This procedure is more tricky to manage as each enzyme is somewhat fragile and has to be applied in an exact sequence and for a brief time only. This results in artificially shortened protein molecule chains which are supposedly faster to absorb by the human body, but often also result in a darker colour and a more bitter taste. Our facility can produce both, but the “classical” isolate with just one enzyme being used to break down the starch and isolating the whole protein molecule for consumption is definitely the bigger product.

Subsequently, the isolated pea mash goes through an initial filtering process: Each of the cloths below is a filter. The starch, being broken down into smaller molecules and being water-soluble, passes through. The protein gets stuck in the filters. This results in the primary raw protein mass with about 60% protein content.

What sets our organic pea protein apart and differentiates us in the market, is the 85% protein purity level. Most of the market offers a standard 80%, but we go one step further requiring double the processing time, resulting in a refined, superior protein of 85%. This is achieved by an extensive 2nd stage of processing consisting of additional washing, cleaning, filtering and cleaning. The more time invested at this stage, the lighter the colour and the more neutral in taste, as well as one of the highest protein content on the market.

The entire process is managed and monitored from a central operating facility onsite, providing full process control. As a matter of fact, this fully automated procedure has minimal human intervention, and turns out high volume, with consistent quality, 24 hours per day during an impressive 365 days per year.

Finally an Amazon-style warehouse takes care of the swift logistical handling of the final product; pallets and container loads are loaded into trucks and after a short ride to the port, are shipped to Europe and the rest of the world.

Crafting Premium Rice Protein Powder

Our journey continued nearby, where we visited our organic rice protein powder producers. Here, too, we were met with exceptional quality standards and a similar commitment to excellence. Like pea protein, rice protein on the market often sits at around 80% purity. But again, we aim for more: our rice protein is processed to reach 85% purity, yielding a product that is finer, more neutral in taste, and distinctly white in colour.

What makes this rice protein especially unique is our producer’s control over the entire supply chain. Unlike some producers who import rice from various countries, our partners cultivate their own rice in China. This control is crucial, particularly when it comes to meeting EU regulations for ‘Mosh Moah’ – industrial oil residues that can present health risks if not managed carefully. Because our producer handles each step, from growing to processing, they can minimise contamination and ensure compliance with these stringent standards.

The Science Behind Superior Protein Content

Producing rice protein with 85% protein content is a meticulous, multi-step process that takes approximately 20 hours from start to finish. Initially, raw rice with just 7-8% protein is soaked in large tanks of water to create a pulp. Similar to pea protein, enzymes are then added to break down the starch into smaller, water-soluble molecules. When the pulp is filtered, the starch passes through while the protein is captured in cloth filters, resulting a raw protein powder with around 70% protein content. This is actually easy to get – many facilities can do this, and is easy to scale volume and to purchase more if needed.

The magic / differentiation of quality happens afterwards in the subsequent refinement, cleaning and purification. Now strict hygiene precautions kick in and is where the real work begins.

In this second phase, the raw protein powder undergoes further purification, where it is filtered, repeatedly washed, and carefully treated to remove residual non-protein substances. Then it comes further down, gets dried, milled and sieved, and again homogenised. This thorough refinement ultimately increases the protein concentration to the desired 85%. Only at this stage does our product gain its signature fine texture and high purity.

Commitment to Quality and Control

Visiting our pea and rice protein powder producers reinforced our confidence and pride in our partnerships where we saw first hand the impressive levels of technology, quality control, attention to detail and commitment to raising the bar for plant-based proteins. Our pea and rice proteins aren’t just products; they are the result of advanced science, trusted partnerships, and a relentless focus on quality.

As plant-based protein demand rises, we remain dedicated to ensuring that every scoop of our product embodies purity, sustainability, and excellence.

Contact us today for more information on pricing and volumes!

© Copyright Abbott Blackstone International GMBH